Menu

Klik dig igennem vores prisberegner og indhent et tilbud på prototyper eller serieproduktion i plast, letmetal eller EPS/EPP.

Fra idé til støbeklart værktøj på to uger.

”De har været lynhurtige og kreative medspillere''

Rasmus Grusgaard, Seniorkonsulent ved Plastindustrien

Inden produktionen satte i gang, assisterede vi NOAQ Flood Protection AB med materialevalg, DFM og flow analyse. På vores in-house værktøjsfabrik fremstillede vi derefter det store støbeværktøj.

Vi udvider endnu engang kapaciteten i plast produktionen med ny sprøjtestøbemaskine.

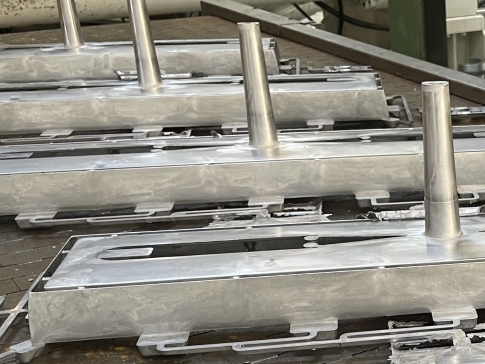

Efter valget faldt på Idé-Pro, har Louis Poulsen fået leveret trykstøbte emner i lige netop den kvalitet og hastighed de efterspurgte.

“Vi når hurtigere til de slutemner vi ønsker”

Bjarne Hechmann, Senior Manager Product Engineering, Louis Poulsen

I samarbejde med gartneriet Wellfarmed, har vi udviklet tekniske EPS emner til et innovativt system, hvor der dyrkes grøntsager uden jord, på få kvadratmeter og med ekstremt lavt vandforbrug.

“De hjalp os til at komme fra idé til produkt på rekordtid.”

Sune Rasmussen, Direktør, Wellfarmed

Vi forstår at effektivitet er i højsæde hos vores kunder og derfor er vi yderst opmærksomme på emnedesign- og konstruktion. Det kan være komplekst at designe emner og for at sikre en effektiv produktionsproces er det vigtigt, at et emne er konstrueret korrekt og nøjagtigt.

Derfor gennemgår vi omhyggeligt hvorvidt dit emne er klar til produktion, når det er færdigtegnet. Er slipvinklen optimal? Er godstykkelsen hensigtsmæssig? Her benytter vi os bl.a. af DFM analyser. Vores standardpraksis inkluderer altid en omfattende kvalitetskontrol – også under produktion for at sikre at produktet lever op til standarderne.

På Idé-Pro har vi store ambitioner for bæredygtighed og tager aktivt ansvar for vores rolle i verden. Vi vil være frontløbere på ansvarlig produktion af prototyper i plast, letmetal og EPP/EPS og ønsker at være et godt eksempel overfor både vores kunder, leverandører, samarbejdspartnere og konkurrenter.

Det gør vi bl.a. gennem et højt niveau med energiledelse- og optimering samt post industry recycling og post consumer recycling ved hjælp af vores in-house ekstruderings- og kompounderingsanlæg. Vi tager også socialt ansvar og ønsker at gøre Idé-Pro til en arbejdsplads med plads til alle, hvor vores medarbejdere er glade for at møde ind.

Med in-house produktudvikling, værktøjsfremstilling, plast-, letmetal og EPS/EPP støberier, målelaboratorie og montage, kan vi hjælpe med alle nødvendige processer. Du er garanteret en kort gennemløbstid, høj fleksibilitet og konkurrencedygtige priser. Idé-Pro er din partner fra idé til prototype, produkt og produktion.