Menu

Several factors played a role in the problem that X Vent faced. They manufactured two of the parts, a wing and a set of spokes, for one of their degassing systems on milling machines. This resulted in:

X Vent wanted to find a more efficient and cost-effective production process. Therefore, they decided to explore the possibilities of injection moulding.

X Vent is a Danish company specialising in ventilation and degassing solutions for land-based aquaculture facing challenges in extreme environments.

By switching from milling to injection moulding, X Vent now avoids the long production time for the wing and the high part price for the spokes.

‘We can get parts with relatively short delivery times, and there is no doubt about the quality.’

Says Thomas Holt from X Vent about the cooperation with Idé-Pro and their now injection-moulded plastic parts.

In general, X Vent discovered many benefits from injection moulding compared to milling:

An alternative to solving the long production time could be to invest in more milling machines. But then X Vent would not get all the benefits of injection moulding.

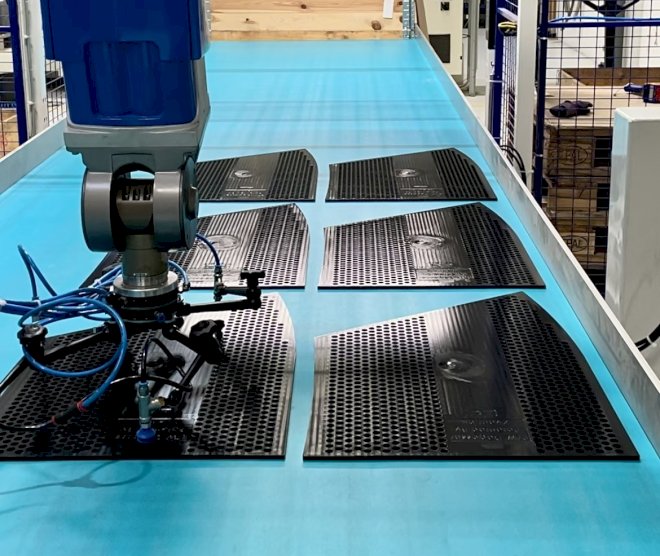

X Vent wing.

A good result with injection moulding starts with the design. When designing parts for injection moulding, it is important that they are designed with, for example, a draft angle so that they can be ejected from the mould tool.

That is why we helped X Vent preparing the plastic parts for injection moulding, thereby ensuring their producibility.

Besides preparing the part designs and injection moulding, we also produced the two mould tools for X Vent's parts in our in-house tool factory in Skive.

Thus, X Vent got a comprehensive solution where part design, tool manufacturing, and injection moulding are all handled under one roof.

We are ready to injection mould plastic parts for you – contact us and we will find a solution that meets your needs.

X Vent spokes.