Menu

We specialise in high pressure die casting prototypes or low-volume production in aluminium, magnesium and zinc. We also do machining from block and investment casting.

In addition, we have a wide range of finishing options and in close dialogue with the customer, we find the manufacturing process that best meets cost, quantity and finish requirements.

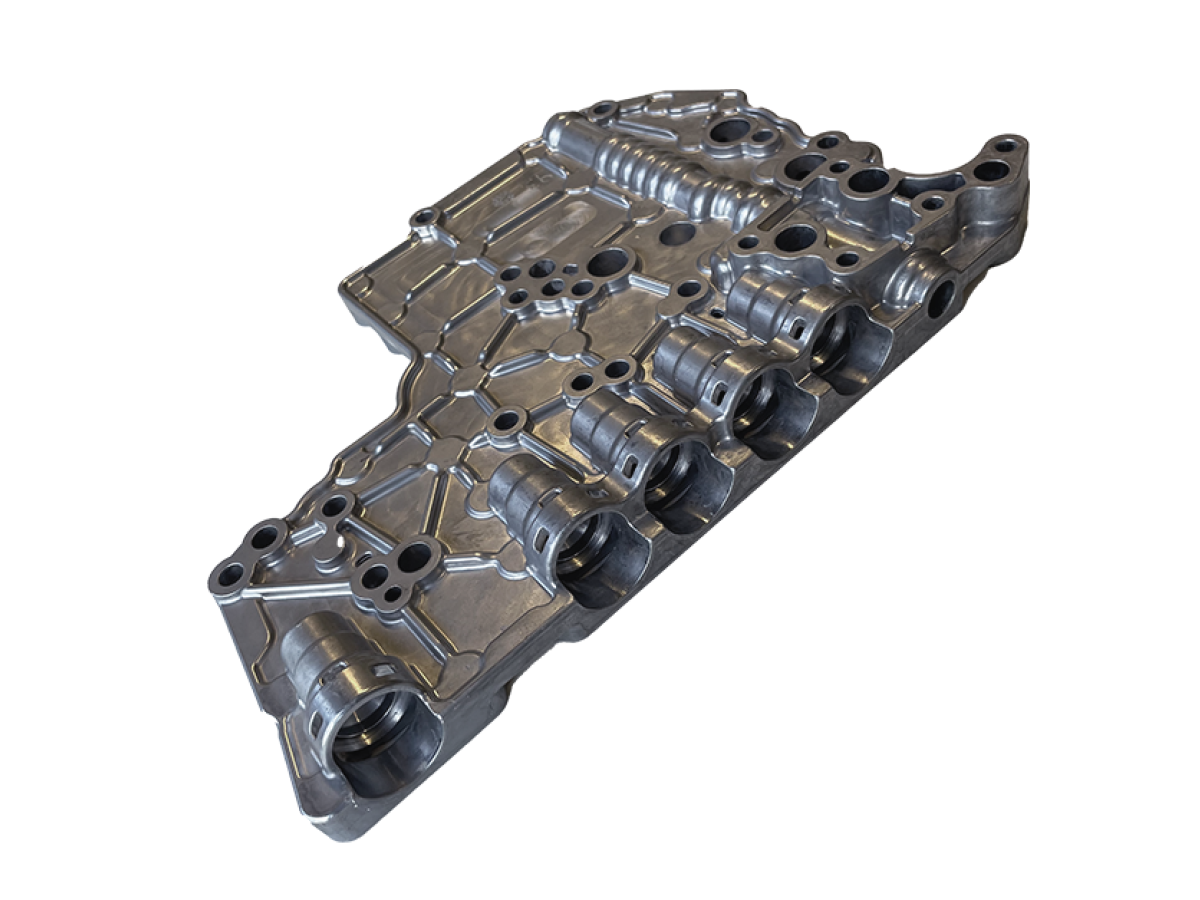

We are experts in high pressure die casting techincal parts in aluminium, magnesium and zinc. With a high capacity, we can die cast parts up to 21.8 kg with a clamping force of up to 1350 T and parts with wall thicknesses down to 1 mm.

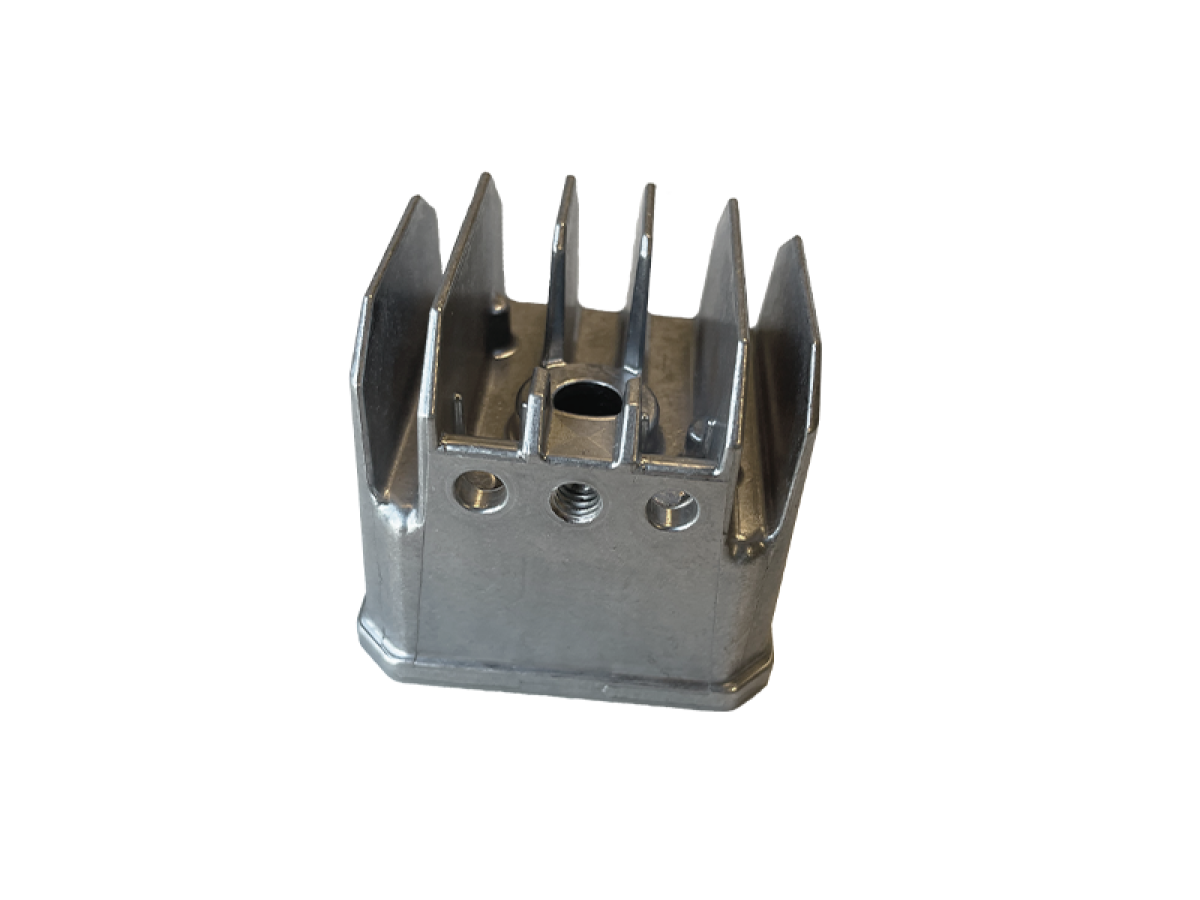

On our hot chamber zinc machine, we can die parts up to 3.4 kg with great speed and precision. All our high pressure die casting machines are fully equipped with peripheral equipment to produce consistent light metal parts.

In our state-of-the-art CNC department, we offer this method where light metal parts are milled directly from the block. This is perfect for complicated parts with fine tolerances, small piece counts and dropout samples. The method is often used for prototyping.

We recommend choosing high pressure die casting and machined from block for light metal prototypes.

In rare cases also investment casting if the part is low volume and complicated to manufacture with traditional casting methods.

We manage a range of post-processing options for your light metal part to achieve the exact finish or tolerances you want.

The options include heat treatment, CNC machining, impregnation, various surface treatments and painting. We handle all post-processing, so you're guaranteed a fast delivery and seamless handover.

We stock a wide range of light metals for high pressure die casting and always help ensure that the material we recommend is the right choice for you.

Material: Aluminium

Process: High-pressure die-casting

Purpose: Prototype

Dimensions:

Weight:

Clamping force:

Surface:

Material: Aluminium

Process: High-pressure die-casting

Purpose: Production

Dimensions:

Weight:

Clamping force:

Surface:

Material: Zinc

Process: High-pressure die-casting

Purpose: Prototype

Dimensions:

Weight:

Clamping force:

Surface: Paint

Material: Aluminium

Process: High-pressure die-casting

Purpose: Production

Dimensions:

Weight:

Clamping force:

Surface:

At Idé-Pro, we specialise in the development and manufacturing of technical EPS/EPP parts with high complexity, so we only need to mould a few parts to get a complete product.

We have a close dialogue with the customer about the part design, and with our extensive knowledge of tool making, we can mould exactly the parts you need. No task is impossible.

EPS is a highly insulating material often used for insulation parts. EPP is an energy-absorbing material used in the automotive industry, for example. Both EPS and EPP are super lightweight materials that can both be used as part of the finished technical product.

Our in-house tool factory also has extensive know-how in manufacturing these special tool types, which are always made in aluminium as it has the right thermal conductivity.