Menu

Our in-house test laboratory plays an important role in our production of prototypes and on-demand parts. Quality is paramount and in the lab we measure and test technical parts to ensure the right quality. Parts can be tested the same day they are manufactured, ensuring not only quality but also efficiency.

Advanced technology

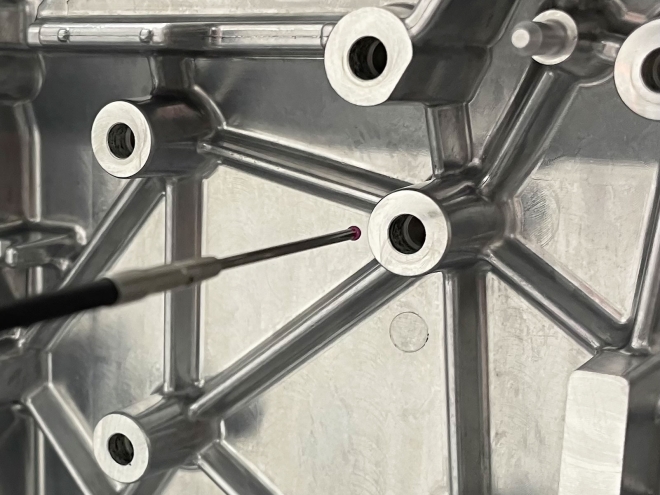

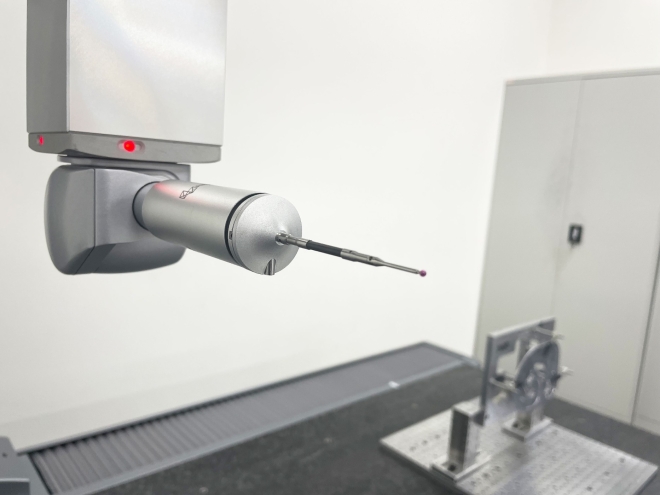

To ensure the highest level of precision, our laboratory is equipped with state-of-the-art measuring equipment, such as our advanced Global S 09.20.08 measuring machine with a working area of 2000 x 900 x 800 mm.

We can test all prototypes and series-produced parts, and to ensure that all tolerances are met to perfection, we offer a wide range of analyses.

We perform advanced leak tests to ensure that products and prototypes fulfil density and safety requirements.

Our test lab can perform precise pressure tests that guarantee your technical items can withstand the forces they will be subjected to in the real world.

We perform spectral analyses to identify and quantify the composition and quality of materials.

With our X-ray and CT scanning technology, we can inspect products in depth and detect any errors or deviations in tolerances and materials.

We offer advanced laser and tactile scanning for precise 3D measurements and surface inspections.

We provide comprehensive documentation of all our tests so you can have full confidence in the quality of your products and prototypes. We are committed to delivering results in record time and with our in-house test lab, we can fulfil your need for accurate measurements with exceptional efficiency.

Contact us today to discuss how we can help you produce prototypes and products that fulfil your technical requirements.