Menu

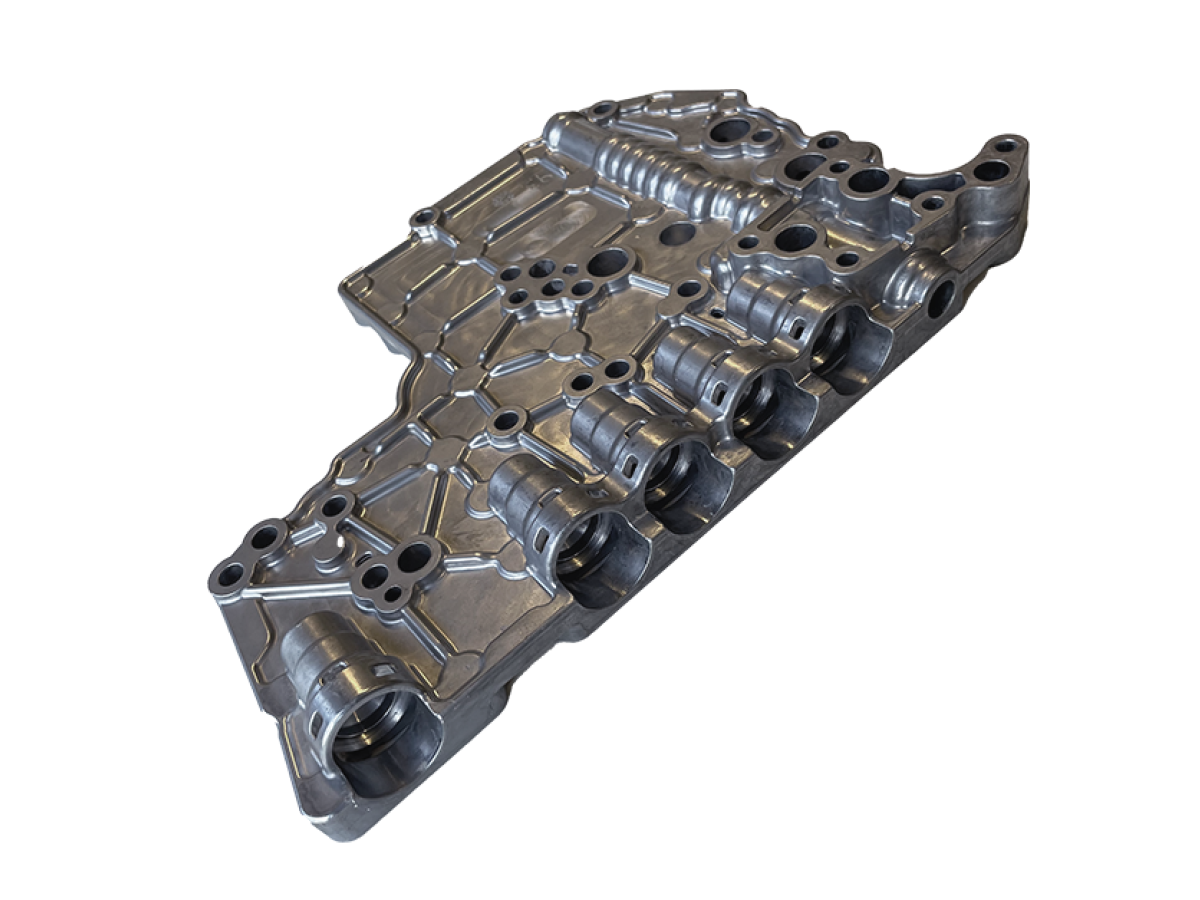

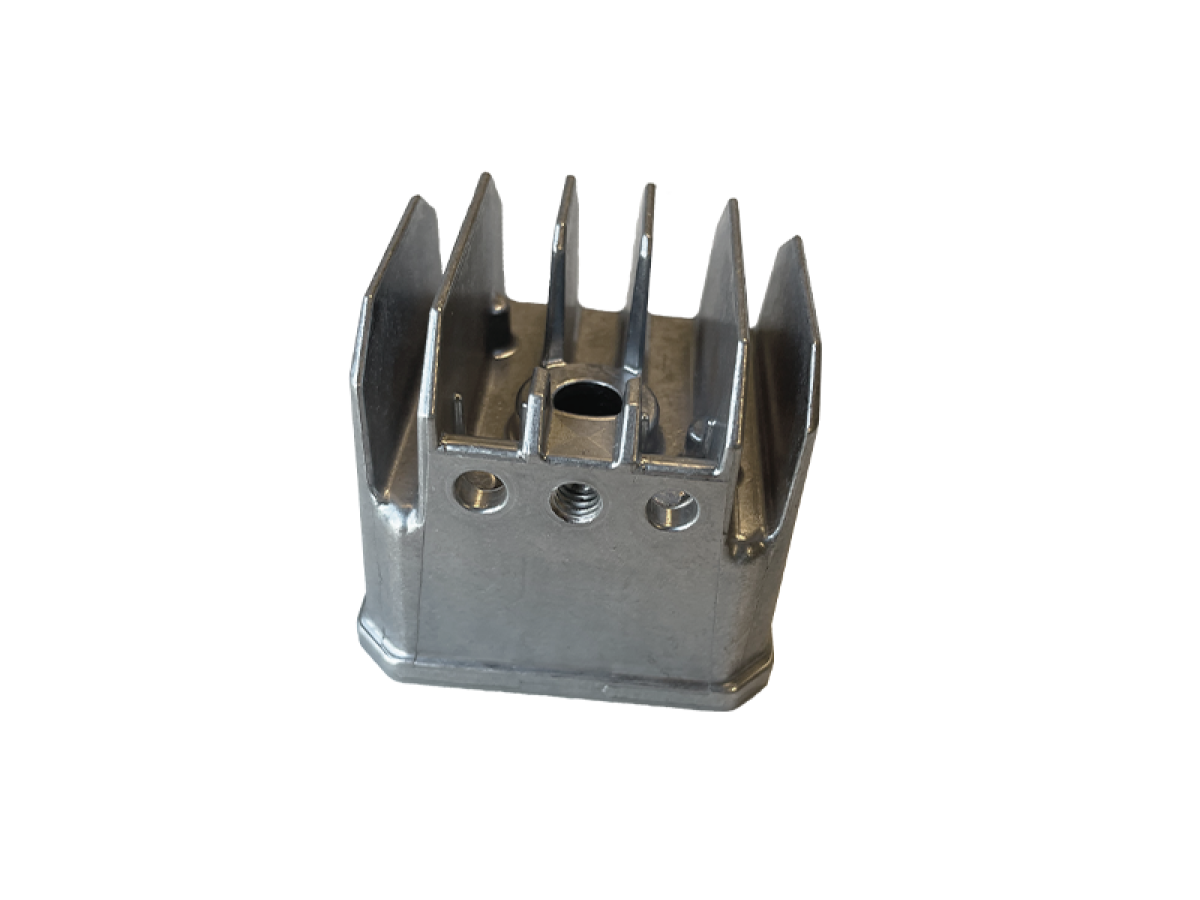

We offer high pressure die casting of prototypes and parts in aluminium, zinc and magnesium. With high capacity in our metal department, we can high pressure die cast parts with wall thicknesses from 1 mm and up to 21.8 kg with a clamping force of up to 1,350 T.

After high pressure die casting, we offer a wide range of post-processes, such as 3-5 axis CNC machining or impregnation, which are completed in our modern machine park.

If measurement and verification of the high pressure die cast parts are required, we can also take care of this in our measuring laboratory.

In close dialogue with the customer, we find the solution that best meets the requirements for costs, quantities and finish.

Aluminium is our most commonly used material. It's an affordable material that is easy to work with.

We stock a wide range of aluminium alloys, of which the most commonly used for high pressure die casting include:

Zinc is good for items that require fine tolerances and smaller wall thicknesses. It is durable, in some cases stronger than aluminium, and is therefore often used for fittings, hinges, etc. Our most commonly used alloy for high pressure die casting is:

Magnesium provides a nice finish and is lighter than aluminium. It is used in products where a lower total weight is required. Our most commonly used alloy for high pressure die casting is:

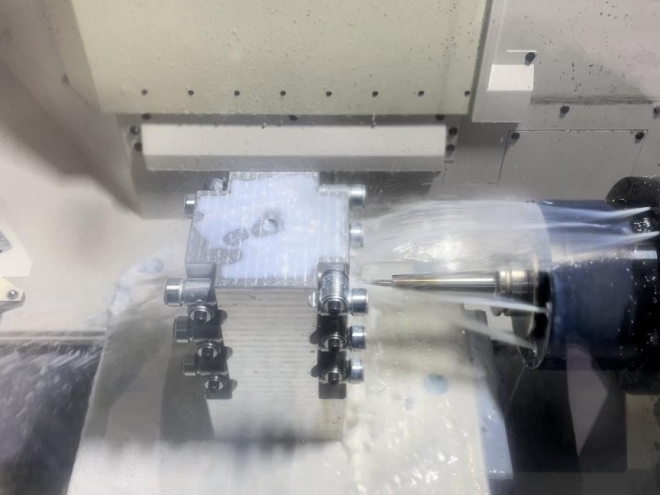

Get fine tolerances on high pressure die cast parts with CNC machining. In the machining department, we have six milling machines with 3-5 axis CNC machining:

On the left, CNC machining in a Makino a40se.

In our state-of-the-art CNC department, we offer this method where light metal parts are milled directly from the block.

This is perfect for complicated parts with fine tolerances, small piece counts and dropout samples. The method is often used for prototyping.

We recommend choosing high pressure die casting and machined from block for light metal prototypes.

In rare cases we also offer investment casting if the quantity is low and the part complicated to manufacture with traditional casting methods.

Material: Aluminium

Process: High-pressure die-casting

Purpose: Prototype

Dimensions:

Weight:

Clamping force:

Surface:

Material: Aluminium

Process: High-pressure die-casting

Purpose: Production

Dimensions:

Weight:

Clamping force:

Surface:

Material: Zinc

Process: High-pressure die-casting

Purpose: Prototype

Dimensions:

Weight:

Clamping force:

Surface: Paint

Material: Aluminium

Process: High-pressure die-casting

Purpose: Production

Dimensions:

Weight:

Clamping force:

Surface: