Menu

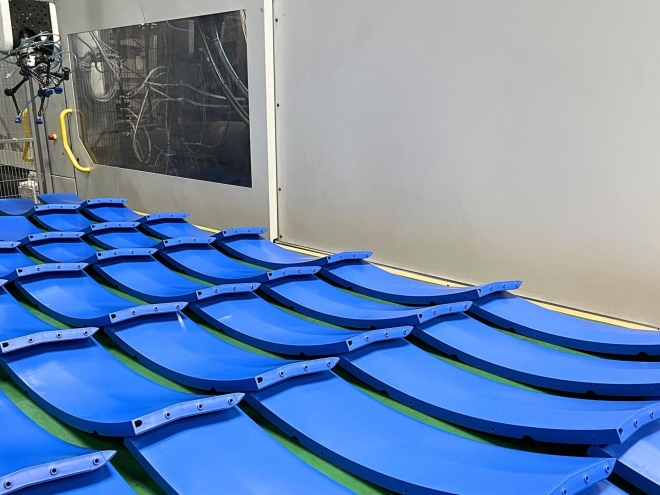

PC/ABS (polycarbonate/acrylonitrile butadiene styrene) combines the durability of polycarbonate with the elasticity of ABS. The material is often used for injection moulded parts that require a long lifespan, high wear resistance and nice surfaces.

The material can be modified with flame retardants in accordance with UL 94, making it suitable for products where fire safety is important. PC/ABS is suitable for both prototypes and series production and is a popular choice among our customers.

PC/ABS provides a good balance between durability and elasticity. With this material, we can deliver quality parts that are made to last.

PC/ABS plastic withstands mechanical stress better than many other types of plastic. This means that the parts retain their shape and function over time. The material's stability in temperature variations ensures precise injection moulded parts.

PC/ABS can be supplied with flame retardant properties in accordance with UL 94, making the material safe to use in demanding environments. It is often used in housings, panels and other parts where both mechanical stability and fire safety are essential.

The material works great for both small and large parts with complex geometry. It enables innovative injection moulding solutions and efficient production of prototypes and series.

At Idé-Pro, we have extensive experience with injection moulding of PC/ABS. Our plastic production offers great flexibility and fast delivery, regardless of the size or complexity of the part.

Prototypes can be fully tested in terms of material selection, design and function, ensuring that the final product meets all requirements. Our foundry is staffed 24/7 and ready for on-demand manufacturing.

As a plastics manufacturer, we understand how important it is to work in a sustainable way, which is why we also have our own compounding facility, enabling us to recycle excess plastic and scrap from the production.

With so many advantages, it's no wonder that our customers often choose PC/ABS for their injection moulded parts. Interested in learning more?

Contact us today to hear how we can help you with injection moulding plastic parts.